|

|

Menu

My 123-3D.ie

This site is protected by reCAPTCHA and the Google

Privacy Policy and

Terms of Service apply.

Don't forget the.....!

123-3D black PLA filament

Popular products

Zortrax M300 Plus

| Zortrax M200 Plus/M300 Plus nozzle set 0.3/.6mm | ||

|

|

|

|

€33.50

(Incl. 23% VAT)

(€27.24 Excl. 23% VAT) |

EU warehouse | |

| Zortrax M200 Plus/ M300 Plus/ M300 Dual brass nozzle, 0.6mm | ||

|

Interested in ordering?

|

||

|

€15.00

(coming soon)

(Incl. 23% VAT)

(€12.20 Excl. 23% VAT) |

||

| Zortrax M300 HEPA cover | ||

|

|

||

|

€271.00

(Incl. 23% VAT)

(€220.33 Excl. 23% VAT) |

EU warehouse | |

| Zortrax HEPA cover filter set | ||

|

Interested in ordering?

|

||

|

€35.50

(coming soon)

(Incl. 23% VAT)

(€28.86 Excl. 23% VAT) |

||

| Zortrax perforated plate M300/M300 Plus | ||

|

|

||

|

€211.50

(Incl. 23% VAT)

(€171.95 Excl. 23% VAT) |

EU warehouse | |

| Zortrax M300/M300 Plus perforated plate cable | ||

|

|

||

|

€10.25

(Incl. 23% VAT)

(€8.33 Excl. 23% VAT) |

EU warehouse | |

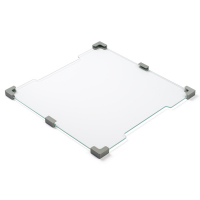

| Zortrax M300 Plus/M300 Dual glass build plate | ||

|

|

||

|

€87.50

(Incl. 23% VAT)

(€71.14 Excl. 23% VAT) |

EU warehouse | |

| Modifi3D repair/modification tool | |||

|

Extra information

|

|||

| Order now, we can ship this today! | |||

|

€34.75

(Incl. 23% VAT)

(€28.25 Excl. 23% VAT) |

in stock | ||

| Modifi3D Pro repair/modification tool | ||

|

|

||

| Order now, we can ship this today! | ||

|

€76.50

(Incl. 23% VAT)

(€62.20 Excl. 23% VAT) |

in stock | |

| 3D Printer starter/finishing/maintenance kit | ||

|

Interested in ordering this?

|

||

|

€84.50

(coming soon)

(Incl. 23% VAT)

(€68.70 Excl. 23% VAT) |

||

| Steelmans 3dB noise reduction feet pads | ||

|

|

||

| Order now, we can ship this today! | ||

|

€17.00

(Incl. 23% VAT)

(€13.82 Excl. 23% VAT) |

in stock | |

| Calex Smart WiFi smoke detector | ||

|

Interested in ordering?

|

||

|

€31.50

(coming soon)

(Incl. 23% VAT)

(€25.61 Excl. 23% VAT) |

||

| Calex Smart mini indoor camera (1080p) | ||

|

|

||

|

€41.50

(Incl. 23% VAT)

(€33.74 Excl. 23% VAT) |

EU warehouse | |

| WOOX smart indoor camera | ||

|

|

||

|

€34.50

(Incl. 23% VAT)

(€28.05 Excl. 23% VAT) |

EU warehouse | |